NEWS&EVENT

- Professional manufacturer of heavy-duty slurry pump -

How to choose the pump sealing method?

Published:

2023-03-23 09:40

Source:

According to the characteristics of the medium conveyed by the slurry pump, it is suitable for conveying solid liquid mixtures containing hard particles.

It is one of the indispensable equipment in mining, metallurgy, coal mining, and other industries. There are mainly packing seal, expeller seal, and mechanical seal, each with its advantages and disadvantages, Select applicable seal to improve service life and reduce economic losses.

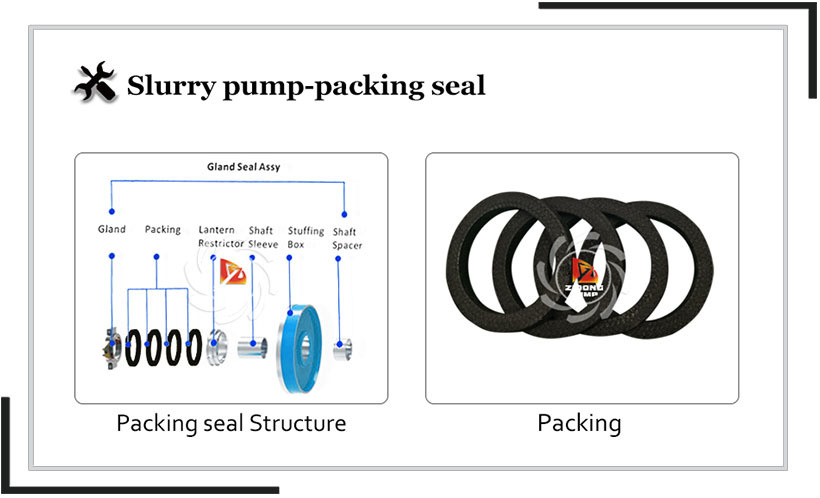

1. Packing seal:

The most common type of seal, simple in structure and inexpensive.

The sealing purpose is achieved by injecting shaft seal water to prevent the leakage of the conveying medium. When transporting corrosive slurry, it may cause corrosion to the filler.

2. Expeller seal:

The reverse centrifugal force is generated by expeller to play the sealing effect.

Add grease to ensure lubrication, easy maintenance, and simple application conditions;

good sealing effect when pressed, but will make the sleeve wear and consume a lot of power.

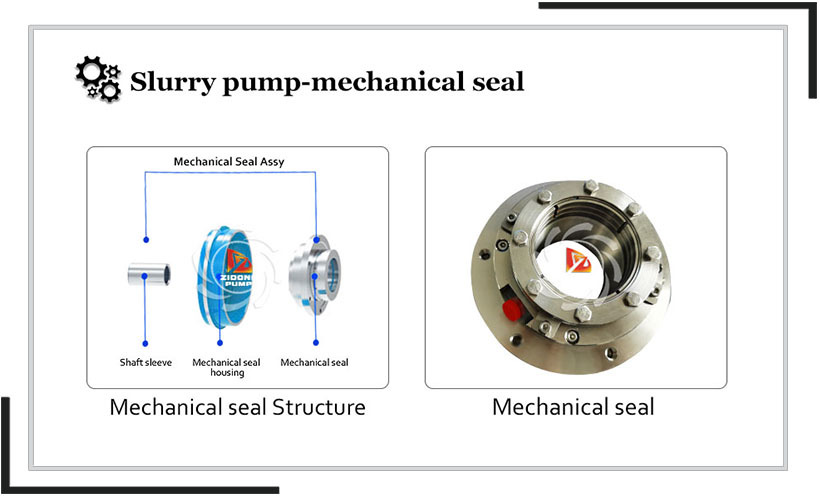

3. Mechanical seal:

Good sealing performance, almost no leakage.

It is suitable for transporting flammable, explosive, high-temperature and high-pressure liquids, making up for the lack of packing sealing. High cost, difficult maintenance.

Each sealing method has its advantages and disadvantages, and the most suitable method can be selected based on the needs of various factors.

Key word:

slurry pump,expeller seal,packing seal,Mechanical seal

Related news