NEWS&EVENT

- Professional manufacturer of heavy-duty slurry pump -

How to select impeller type

Published:

2023-07-27 11:39

Source:

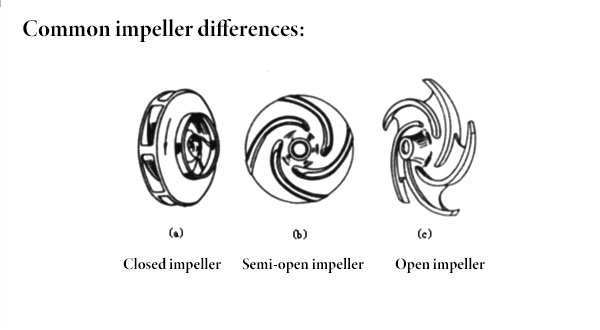

The impeller, the component that transmits energy from the fluid, can be classified according to its shape and the opening and closing conditions.

A. Different forms of blades

1. Closed impeller: blade ends have a cover, its impeller flow channel is closed. High operating efficiency, can be a long time smooth operation. Closed impeller is mostly used to convey high head media.

2. Semi-open impeller: the blade and the back cover of the wheel are composed, and compared with the closed impeller, there is no front cover, its impeller flow channel is semi-closed, can be used to convey impurities in the media. But due to the solid particles abrasion flow channel, it will cause the pump efficiency to be reduced.

3. Open impeller: only the vane without front and rear cover, the impeller flow channel is completely open, impeller efficiency is low, less application, can be used to transport viscous media.

B. Impeller multiple materials:

The more common impeller materials are cast iron, stainless steel, high chrome alloy, rubber, polyurethane, etc..

In the choice of impeller is to choose the right material according to the medium it conveys, for example, used to convey a strong abrasive or corrosive fluid media, can use high chrome alloy material or rubber material impeller.

C. how to choose:

Centrifugal pump impeller design selection, usually need to consider energy efficiency, cavitation performance, operating range, but also according to the case of the transport medium selection of materials, structural forms, use of working conditions, etc.

Key word:

impeller,high chrome alloy,rubber ,metal impeller,slurry pump,sand pump

Related news